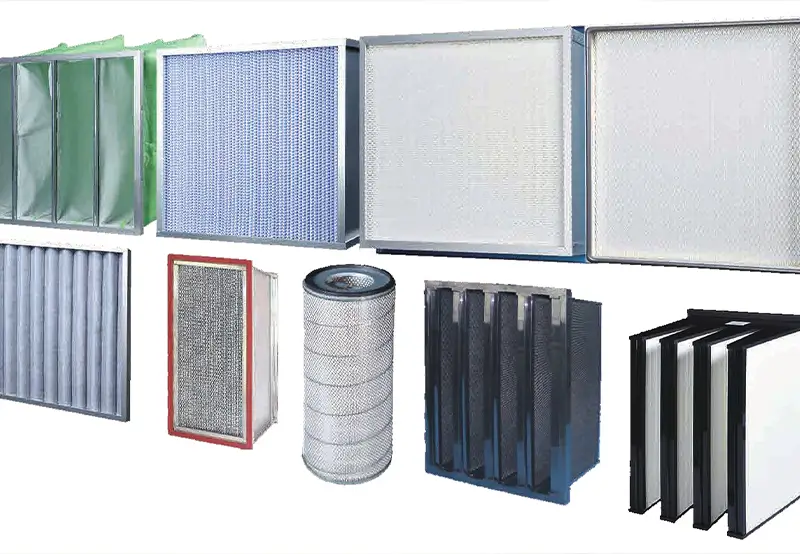

What Are the Different Types of Industrial Air Filters – A Comprehensive Guide

The presence of air filtration in industries has been very crucial to the preservation of air quality and safeguarding of both the environment and machinery in any industry. Understanding the different types of air filters available, the technology behind them, and their applications is vital for choosing the right system. This comprehensive guide will explore the types of air filters commonly used in industrial settings, focusing on key options like activated carbon filters, HVAC air filters, cartridge filters, and other advanced air filtration technologies.

Understanding Industrial Air Filters

The importance of filtration of air can be applied in diverse things that come to the picture of industries either in plant manufacturing to the HVAC. Air filters in industry assist with filtering things like dust, smoke, fumes, and gases that can potentially ruin equipment, interrupt operations, or affect the health of the workers. Industrial air filters come in many forms and all have certain air quality needs and functions to serve.

1. Activated Carbon Filters

Activated carbon filters are widely recognized for their ability to remove gases, odors, and volatile organic compounds (VOCs) from the air. Activated charcoal is the essence of activated carbon filtration technology and has a large surface area where contaminants adsorb. Such filters work quite well when there is a need to filter air that has been contaminated with organic chemicals, fumes and smells.

In industrial settings, activated carbon filters are used in air scrubbers and exhaust systems to control odors and protect sensitive equipment from harmful chemicals. As one such example, they have been routinely used in food processing, place manufacturing, and chemical facilities, where air purity is declared a priority.

Activated carbon filtration process occurs due to adsorption whereby contaminants in the air are attached to the surface of the carbon. This makes activated carbon filters ideal for industries that need to mitigate air pollutants that conventional filters might not capture effectively.

2. HVAC Air Filters

HVAC air filters are necessary to keep air in industrial and commercial buildings clean and sanitary. They also remove dust, pollens, mols, bacteria, etc. They also filter out dust, pollen, mold, bacteria, etc. before the air is circulated, which ensures health of occupants and efficiency of the system. Different types of HVAC air filters exist, from basic fiberglass to advanced HEPA filters. The selection is based on the quality requirements of the air, hospitals would usually need the high-efficiency filter whereas factories might choose lower restrictive filters. Higher MERV rated filters will capture a smaller particle size but may reduce airflow resistance. Proper selection and balance of HVAC air filters ensure optimal performance and energy efficiency.

3. Cartridge Filters

Cartridge filters are widely used in industrial air filtration due to their high efficiency and compact design. These are made of cylindrical cartridges filled with media such as fiberglass or pleated paper and they work well whether they are collecting coarse or fine particles. Common in dust collection systems, ventilation units, and air purifiers, cartridge filters are especially valuable in industries such as woodworking, mining, and cement production. They possess a high filtration rate that assures you clean air, and they are easily removable which gives the maintenance cheap, simple and highly effective.

4. HEPA Filters (High-Efficiency Particulate Air Filters)

HEPA filters have become well known because of their capability of trapping very fine particles. As an industry standard, a HEPA filter should be able to capture airborne particles with a diameter of 0.3 microns to be no less than 99.97 percent. This means the HEPA filters can be very effective in cases that demand a high degree of air purity like clean rooms, hospitals and laboratories.

HEPA filters are commonly combined with other types of air filtration technology such as activated carbon filters in order to guarantee that not only particulate but also gaseous pollutants are eliminated in the air. To facilitate industrial work, HEPA filters ensure a healthy staff job position by keeping the workplace debris of allergens, bacteria, and other toxic substances out of the air.

5. Electrostatic Precipitators

Electrostatic precipitators represent a stage of the air filtration equipment that utilizes electric charge to take particles out of the air. The filters are commonly employed by industries that are concerned with fine particulate matter, i.e., either soot or dust. Electrostatic precipitators employ the collection of negative particles under a negative charge and manage through a filter as they come into contact with positively charged collector plates.

This technology is usually used in a power plant, chemical manufacturing plant, and other heavy industries where high-efficiency particulate filtration is needed. Electrostatic precipitators are efficient and minimize the airflow resistance through particle capture when combined with low energy requirements even in large systems.

6. Bag Filters

Bag filters form an important component of dust collection systems in sectors like cement plant, food industries and mining. They are so effective in removing large quantities of air and being able to trap minute particles too to make the released air back to the environment, to be of the required standard.

In industries such as cement production, food processing, and mining, bag filters are an essential part of dust collection systems. They are highly effective for filtering large volumes of air and can capture fine particles, ensuring that the air released back into the environment meets regulatory standards.

7. Pleated Filters

Pleated filters are constructed so that the filtration medium is folded (and has pleats) to maximize its surface area and improve the ability of the filter to trap contaminants. Such filters are common in stand alone air purifiers, as well as industrial HVAC systems. Having a large range to capture many particles (dust, pollen, and pet dander), pleated filters can be applicable to diverse industrial and commercial uses.

Pleated filters tend to be more effective than ordinary flat filters, and the higher surface area enables them to be used longer before they have to be changed. These filters find application in places where levels of air quality are paramount yet high levels of filtration efficacy such as those provided by HEPA filters is unnecessary.

8. Gas Phase Filters

Gas phase filters contain activated carbon filters and are specifically meant to remove gaseous pollutants in the air. They apply the filters in the atmospheres where the air has harmful gasses like sulfur dioxide, ammonia, or volatile organic (VOCs). In Chemical processing facilities, Waste water treatment plants and in areas where clean air involves the elimination of gaseous pollutants, gas phase filtration is a critical process.

Conclusion

An appropriate industrial air filter is essential in determining the quality and safety of the air in a facility. Air filters are designed differently to fulfill the specific tasks; some are used to neutralize the odors and gases by application of activated carbon air filter while others are applied to solve the indoor environment problems using the HVAC air filter. To obtain high cleanliness levels, cartridge filters, HEPA filters and electrostatic precipitators are indispensable, whereas the bag filter and the pleated filter are the ones used in particulate-laden situations.

Finally, the future temperature technology to be used will be contingent on the uniqueness of the industry, filtration degree necessary and the nature of the contaminants. Learning about the pros and uses of each type of filter, industrial facilities will be able to make wise conclusions that ensure pollution control and enhance the quality of air, prevent equipment corrosion, and safeguard the health of workers.

Frequently Asked Questions (FAQs)

Industrial air filters are designed to remove airborne contaminants, such as dust, pollutants, gases, and particulate matter, from the air in various industrial environments. This helps to maintain air quality, protect equipment, improve worker health, and comply with environmental regulations.

Activated carbon filters are primarily used to remove gases, odors, and volatile organic compounds (VOCs) from the air. They are effective in environments where chemical fumes, smells, and organic contaminants are present, such as in chemical plants, food processing facilities, and pharmaceutical industries.

HVAC air filters work by trapping dust, pollen, bacteria, mold spores, and other particulates from the air that circulates through an HVAC system. By filtering out these contaminants, HVAC filters help improve air quality, protect HVAC equipment, and ensure a comfortable environment.

HEPA filters are designed to capture 99.97% of particles that are 0.3 microns in size, making them highly effective in environments that require high filtration efficiency, such as clean rooms, hospitals, and laboratories. Other air filters, like pleated or bag filters, may capture larger particles but are less effective at filtering extremely fine particles.

Cartridge filters are used in air filtration systems to capture both coarse and fine particles. These filters are commonly found in dust collection systems and air purifiers in industries like woodworking, mining, and cement production, where large volumes of air need to be filtered efficiently.