Solar Mounting Systems: Should You Choose Steel or Aluminium?

With the rise of renewable energy and the growing adoption of solar power, the importance of efficient and reliable solar mounting system solutions cannot be overstated. While solar panels often steal the spotlight, the unsung hero that ensures their stability and performance is the solar panel mounting structure material. When it comes to selecting the best materials for these structures, two options stand out: steel and aluminium. Each has unique advantages and challenges, and understanding these differences can help you choose the best solar racking system for your project.

In this blog, we will delve deep into the steel vs aluminium debate and guide you on making an informed choice based on various factors such as cost, durability, weight, corrosion resistance, installation ease, and application suitability.

Why Material Choice Matters in Solar Mounting Systems

A solar mounting frame is the backbone of a solar energy system. It secures the panels in place, withstands environmental stress, and optimizes panel orientation for maximum energy generation. The selection of the solar panel mounting structure material influences not just the structural integrity but also the system’s longevity, installation cost, and maintenance.

Whether you are working on a residential rooftop installation, a large commercial array, or a ground-mounted farm, choosing the right material is crucial for the overall success of your solar mounting system solutions.

Steel: The Sturdy Classic

Steel, especially galvanized steel, is widely used for solar mounting structures because of its durability and affordability.

Advantages of Steel

1. High Strength and Load-Bearing Capacity

- Steel has high load-bearing capacity and can bear heavy loads, thus supporting high wind speed or snow load areas.

- Perfect for utility-level and large-scale projects where structural strength matters the most.

2. Cost-Effective

- Steel is relatively less expensive compared to aluminium in raw material prices.

- A good balance between performance and cost, particularly for bulk applications.

3. Durability with Galvanization

- Steel resists corrosion and rust once galvanized or coated.

- Steel solar mounting frames can be used for decades with reasonable maintenance.

4. Versatility

- Steel is easily fabricated into different profiles and shapes to suit custom solar mounting structure designs.

Disadvantages of Steel

1. Heavier Weight

- Steel structures are significantly heavier than aluminium, which increases transportation and handling costs.

- May not be suitable for lightweight rooftops or mobile applications.

2. Corrosion Risk

- Although galvanization reduces rust, scratches or wear on coatings can lead to corrosion over time, especially in coastal or humid environments.

3. More Labour-Intensive Installation

- Due to its weight and need for precise welding or bolting, installation takes longer and requires more effort.

Aluminium: The Lightweight Contender

Aluminium has become increasingly popular in modern solar mounting system solutions for its lightness, corrosion resistance, and sleek aesthetics.

Advantages of Aluminium

1. Lightweight

- Aluminium is about one-third the weight of steel.

- Ideal for residential rooftops, carports, and installations where structural load is a concern.

2. Corrosion Resistance

- Naturally resistant to rust, even in salty or coastal conditions.

- Requires little to no maintenance once installed.

3. Ease of Installation

- Easier to cut, drill, and assemble on-site.

- Quicker installation reduces labour costs and project timelines.

4. Sleek and Modern Appearance

- Its clean finish and modern look appeal to clients who value aesthetics.

5. Recyclability

- Aluminium is 100% recyclable without losing quality, aligning with the sustainability goals of solar projects.

Disadvantages of Aluminium

1. Lower Strength

- Not as strong as steel under high loads; may require thicker or more components for similar support.

- May flex or deform under heavy snow or wind unless carefully engineered.

2. Higher Material Cost

- Raw aluminium is generally more expensive than steel.

- Can increase project costs, especially for large-scale systems.

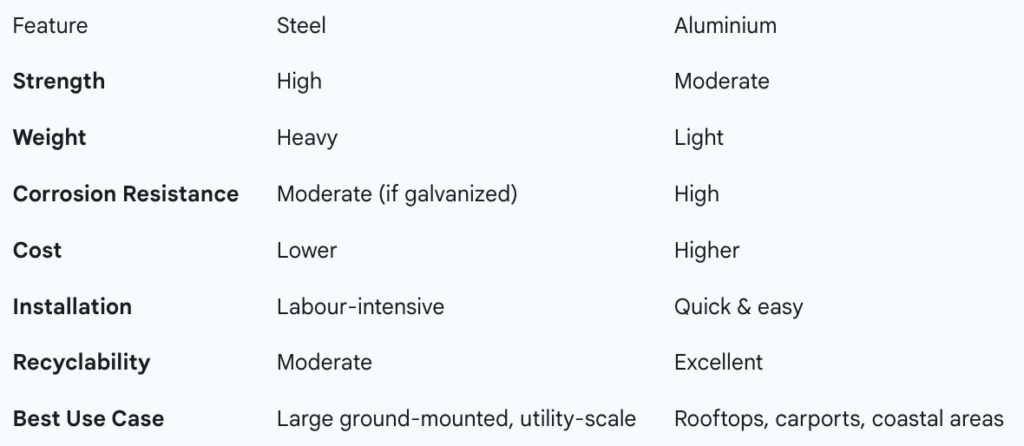

Head-to-Head Comparison: Steel vs Aluminium

Choosing the Best Solar Racking System

To choose the best solar racking system, consider the following factors:

1. Type of Installation

- In case of rooftop systems, it is expected that the user prefers aluminium since it weighs less.

- In the case of ground-mounted or utility-scale systems, support and cost-effective production are achieved better with the use of steel.

2. Environmental Conditions

- It is suited in the coastal regions, where salt corrosion is a problem, and due to its natural ability to resist rust, aluminium is best suited.

- Steel may have to be preferred in snowy or windy areas because of strength.

3. Budget

- Aluminium may be more expensive in its purchase but reduces in the cost of installation and maintenance.

- Steel is cheaper in terms of material costs which may be an advantage to large scale ventures.

4. Aesthetic and Space Constraints

- In case design and aesthetics are an issue (e.g. solar pergolas or urban rooftops), aluminium will offer a cleaner appearance.

Hybrid Systems: The Best of Both Worlds?

Many modern solar mounting structure providers now offer hybrid systems that combine steel and aluminium for optimized performance.

- Steel Base + Aluminium Rails: Common in residential projects where the base provides strength and the rails offer ease of installation.

- Galvanized Steel Anchors + Aluminium Mounts: Used to balance corrosion resistance with cost.

These hybrid systems are often considered the best solar racking system options in terms of performance, cost, and longevity.

Future Trends in Solar Mounting System Solutions

As technology evolves, new materials like anodized aluminium alloys and coated steels are improving the longevity and functionality of mounting systems. There’s also growing emphasis on modular, pre-fabricated, and adjustable solar mounting frames that speed up installation.

Sustainability is another focus—manufacturers are leaning toward materials with a smaller carbon footprint and longer recyclability, ensuring that the solar panel mounting structure material aligns with the eco-friendly goals of solar power itself.

Final Verdict: Steel or Aluminium?

There’s no one-size-fits-all answer. The right material for your solar panel mounting structure material depends on your specific project needs. Here’s a quick guide:

Go for Aluminium if:

- You’re installing on rooftops or carports.

- You need corrosion resistance (e.g., coastal or humid climates).

- Installation speed and aesthetics matter.

Go for Steel if:

- You’re working on a large-scale or high-load project.

- Budget constraints are tight.

- The system will face harsh environmental loads (snow, wind).

Either way, investing in quality solar mounting system solutions ensures long-term stability, safety, and performance of your solar setup.

Frequently Asked Questions (FAQs)

Aluminium is generally the preferred choice for rooftop installations due to its lightweight nature, corrosion resistance, and ease of installation. It reduces the load on the structure and works well in coastal or humid environments. If strength is not a major concern, aluminium offers a reliable and long-lasting solar mounting system solution for rooftops.

Steel provides higher structural strength and is ideal for large or ground-mounted installations. However, aluminium resists corrosion better, especially in coastal or industrial zones. When it comes to long-term durability in harsh weather, aluminium often requires less maintenance, while steel solar mounting frames may need protective coatings or galvanization to match longevity.

Steel is typically more cost-effective in terms of raw material pricing and is widely used in utility-scale projects. However, the best solar racking system balances cost with ease of installation and long-term performance. While aluminium may be more expensive initially, it can save on labour and maintenance costs in the long run.

Yes, hybrid systems are becoming increasingly popular. For example, using a steel base for strength and aluminium rails for corrosion resistance and ease of assembly offers the best of both worlds. These systems provide optimized solar mounting system solutions for varied applications and environments.

Aluminium is the better choice for coastal areas due to its superior corrosion resistance. Salt-laden air can quickly corrode steel, even if it is galvanized. For long-lasting solar mounting frames in such environments, aluminium ensures better performance and lower maintenance needs.